Key industries in the Lodz Zone

The modern services industry, the pharmaceutical and cosmetics industries, the manufacture of household appliances, the ceramics industry, the manufacture of all types of packaging... over the past 20 years, Lodz Special Economic Zone has issued more than 300 business licences for investors - both large, multinational corporations and local, family-run businesses.

What does the future hold for the household appliances industry in Europe and in Poland? What impact will the development of new technologies have on the situation in this sector? How important will the new generations of consumers and employees be for the market? These issues were discussed by members of the industry, experts, representatives of public authorities, developers and general contractors at the International Forum of European Manufacturers and Suppliers of Household Appliances, which took place in Łódź on 16 and 17 May. Lodz Special Economic Zone was the main patron of this event - and this was by no means by accident.

‘The household appliances sector is one of the best represented industries in Lodz Special Economic Zone’, declared Agnieszka Sygitowicz, deputy chief of the Zone.14 businesses representing this industry currently operate in the Zone; they have received a total of 29 licences in connection with new investments, which created almost 6 thousand jobs. The total investment amounted to PLN 2.3 billion.

Whirlpool (formerly Indesit) is one of the Zone’s biggest investors from the household appliances industry. The company estimates that it has been able to employ approximately 2500 people thanks to receiving licences to operate in the Zone, including more than 1400 in Radomsko. Investment expenditure related to these operations reached the sum of approximately PLN 0.5 billion.

‘The subzone in Radomsko is an excellent example of how the Zone can rise up to tackle the challenges it faces, in particular to ensure revitalisation of industry in areas with a high rate of unemployment, resulting from the bankruptcies of the industrial plants that used to be located there’, said Zygmunt Łopalewski, spokesman for the company. ‘When we came to Radomsko 10 years ago, the unemployment rate was close to 20%, we were the first large foreign company to decide to invest there. Today, businesses operating in the Radomsko zone employ several thousand people and have contributed to the alleviation of unemployment issues, not only in the town itself, but in neighbouring areas as well. We were able to do that thanks to the excellent preparation of the land and comprehensive investor services. The Radomsko plant is our showpiece’, the spokesman added.

Zygmunt Łopalewski stressed that the partnership between his corporation and Lodz Special Economic Zone has always run very smoothly, largely thanks to people working for the Zone.

Łopalewski was full of praise for the Zone’s representatives: ‘We’ve implemented both huge projects, like the plant in Radomsko, worth more than PLN 20 million in total, as well as smaller ones. We’ve always supported the Zone’s initiatives, including those intended to stimulate the job market, for example the ‘Education Zone’ project. We’ve worked with all the different management boards of the Zone, the first question that each of them asked us was usually “How may we help you?”’. The partnership between another leading household appliances corporation - BSH - and the Zone resulted in the issuance of no less than 6 business licences. The six investments made by BSH in the zone include a dryer factory, certain shared service centres and a research and development centre working on new models of clothes dryers.

‘The fact that most of our obligations as regards the value of investments and declarations on the number of employees we intend to hire have been exceeded several times is proof positive of the professional and friendly nature of our relationship with the Zone’, said Andrzej Maślak, spokesman for BSH. On 9 May 2017, the company obtained its sixth licence to invest in the Zone, concerning its new Research and Development Centre, where new products will be designed and innovations in the field of clothes washing and drying will be implemented.

‘This new project is another chapter in the new history of our company’s Polish operations. The newly-constructed centre will be BSH’s most modern facility of this type and will be equipped with its own high-tech laboratory. In accordance with our plans, the R&D Centre will employ 150 highly skilled professionals from various fields related to the design of new products and innovative solutions’, said Andrzej Maślak.

SERVICES

The Zone is not only about manufacturing. Recent years have brought an influx of investment in the broadly-defined services sector. Infosys BPO Poland, a company specialising in outsourcing business processes, has been granted two licences to operate in the Zone.

‘The dynamic development enjoyed by Łódź would not have been possible without the open and proactive attitude of entities responsible for investor services, such as Lodz Special Economic Zone’, said Agnieszka Jackowska-Durkasz, managing director at Infosys Poland. ‘The investment-friendly atmosphere in the city was primarily made possible thanks to the dynamic and professional actions of the Zone’s representatives. Thanks to our collaboration with the Zone, we were able to complete our projects much more efficiently. As a result of our project, we were able to increase our workforce by 260 new jobs and today it numbers 2700 employees,. The expenditure we laid out in connection with that project mostly related to the expansion of our offices and technical support facilities. In January, we obtained our second licence to operate in the Zone, which will ensure the continued rapid development of our business and the creation of additional jobs. This new licence signals that our business here is expanding, partly as a result of the increased complexity of the processes we service’, added Agnieszka Jackowska-Durkacz.

So far, Fujitsu has created more than 1900 jobs in Poland, one third of those were made possible by joining Special Economic Zone. The first licence enabled the company to create 408 full-time jobs, the second - a further 250.

‘Our relationship with the Zone enabled us to create jobs for programmers, IT specialists and financial experts. We’ve invested in the development of specialist jobs, which are the most sought after among employees and involve the performance of advanced tasks requiring advanced skills and expert knowledge. Our partnership with the Zone is one of the reasons why our current operations are so diverse - we have five service lines, and our hiring ads are aimed at programmers, IT specialists, financial experts or people fluent in foreign languages’, said Piotr Jankowski, managing director at Fujitsu GDC in Lodz.

Jankowski stressed the importance of the Zone for the entire Lodz region: ‘The Zone is one of the reasons why new investments keep being made in the region, resulting in the creation of new jobs, including those that I believe to be most valuable - jobs for the best professionals in a given field and for young, ambitious people only just entering into the job market. We’re happy that we can employ such talented people in our company. Every day I can see how the energy and creativity of these brilliant people contributes to the extraordinary ambience that our company is famous for. It’s thanks to this ambience, this intangible “je ne sais quoi” that eight out of ten Fujitsu employees declare that they would recommend working in our company to their friends’, said Piotr Jankowski.

Another company which was given a licence to operate in Lodz Special Economic Zone is Ericpol Telecom, originally from Lodz (currently part of the Swedish Ericsson Corporation) and representing the IT industry. Investment made by the company has left a lasting mark on the panorama of the city, as the company erected a new and impressive office building on the former site of the derelict Olimpia swimming pool. In 2015, the building received an award from the Polish Architects’ Association, proof positive of the quality of its design. The Association found the building, named the Ericpol Software Pool, to be the best architectural structure in Poland in the category of public utility buildings - office buildings. The office building cost PLN 40 million and is home to 800 employees, mostly people who had already worked for Ericpol, but upon obtaining a licence to operate in the Zone, Ericpol declared that it would create at least 100 new full-time jobs.

WELL-KNOWN CORPORATIONS

The international Procter & Gamble Corporation has been investing in Lodz Special Economic Zone for several years. Gilette, now part of P&G, built its razor factory at the beginning of the previous decade. In 2007, Procter & Gamble announced its plans to build its largest cosmetics factory in Europe; the grounds of the former sport airfield in Aleksandrów Łódzki were incorporated into the Zone in connection with this project. An interesting fact is that P&G’s distribution centre in the Warsaw district of Targówek also constitutes part of the Zone, as the scope of the Zone reaches outside the province of Lodzkie. Other areas incorporated into the Zone can be found in the provinces of Mazowieckie and Wielkopolskie.

Another international corporation, ABB, has also invested in Aleksandrów Łódzki. In 2008, the company opened its electric motor factory in the town, and later completed additional projects, including a medium voltage converter and electric traction power system factory.

Well-known companies from the pharmaceutics and cosmetics industries can also be found in the Zone. Investors include Aflofarm and Adamed (in Ksawerów), as well as Delia Cosmetics, operating in Rzgow.

Manufacturers of various types of packaging form a significant part of the investors operating in the Zone. One such company is Amcor, one of the leaders in the global packaging market. There’s also Albea from Lodz, manufacturer of the plastic components and packaging, used in cosmetics and pharmaceutics industry. Albea is in fact the first company to have invested in the Zone, as licence no. 1 was never implemented.

‘It was a great opportunity for a small company with great plans and ambitions; as it turned out, we were able to fully grasp this opportunity. It facilitated our true start in the industry and enabled us to enter the Polish and European cosmetics packaging market with a bang’, recalled Krzysztof Kosiński, chief executive at Albea.

‘Thanks to the impetus we received from the Zone in the early period of our operations, today we can boast many merits and awards from competitions, including second and third prize in the ‘Safe Working Environment’ competition and the Lodz Quality Award. We were also chosen as the best company in Lodz region in a poll organised by the Regional Association of Private Employers in the Łódź Region ‘Lewiatan’ (2009 Company of the Year) and received the title of Leader of Modern Technologies from the Institute of New Technologies’, added Kosiński.

According to the chief executive, the first licence, issued in 1998, required the company to create 45 new jobs, the second licence, issued in 2011, included the requirement to hire 10 new employees. In general, however, since moving to the Zone the company has created many more jobs than required by the licences - as many as 220 new employees were hired, five times as many as the company employed back when its offices were located outside the Zone.

‘When investing in the Zone, we fully reconstructed a defunct cotton mill once used by the Uniontex textile plant, shoddily-built at the tail end of the 1970s and later damaged through several years of improper use, and we adapted it to fit our needs’, said Krzysztof Kosiński. ‘We converted one large manufacturing area with a surface of almost 5000 square metres into office, shared and technical spaces. We completely replaced the surfaces of the walls and the roof; fully adapted the building to meet current energy requirements; we laid a modern floor and installed a full technical infrastructure typical of modern plants in this industry. We created a cutting-edge and friendly work environment, making sure to include parking areas, bicycle sheds and environmental amenities. We monitor our impact on the natural environment and the local community. We try to repay for the help we received by closely cooperating with technical schools, higher education institutions and charities‘, added the chief executive.

CERAMICS

The country’s leading players in the manufacture of ceramic tiles are enjoying a booming development in the Zone. In November 2016, Ceramika Tubądzin opened a porcelain stoneware tile factory in the Sieradz subzone. Tiles manufactured in the plant can be as large as 120 x 240 cm - until the factory opened, no Polish manufacturer had produced tiles of this size. The plant was erected at a rapid pace - construction work took only 10 months. Andrzej Wodzyński, owner of Grupa Tubądzin, said last year that opening a new factory would allow his company to increase its manufacturing capacity from 12 to 15 million square metres of tiles per year. The factor in Sieradz is just the latest of Ceramika Tubądzin’s investments in the Zone - licences were previously granted in respect of projects in Tubądzin and Ozorków.

Ceramika Paradyż is another leading company in the industry; it obtained its first licence to operate in the Zone as early as in 2000.

‘We are very happy with our relationship with Lodz Special Economic Zone, which dates back over 17 years now’, said Tomasz Popielawski, spokesman for Ceramika Paradyż. ‘We value our partnership based on mutual respect and the professional services and broad support in legal and formal matters provided by the Zone. We participate in interesting projects and meetings organised by the Zone. Recently we were able to meet delegates from the Bureau International des Expositions and sign our declaration of support for Lodz’s bid to host EXPO 2022. So far, we’ve obtained seven licences to operate in the Zone, which certainly assisted in the rapid development of our company and the entire region. We’ve invested more than PLN 600 million in the Zone and currently employ more than 1300 people. We’ve constructed two new ceramic tile manufacturing plants and Europe’s most modern Commercial and Logistics Centre in addition to expanding three existing plants and equipping them with innovative technologies. Our new subsidiary, Sławno Cerranova, will invest more than PLN 120 million in the Zone and create at least 82 new jobs’ added Popielawski.

The Sławno Cerranova factory will be built with a total area of 12.33 hectares, located in the Sławno municipality, and will specialise in the manufacture of large-format slabs and smaller ceramic tiles, produced using the innovative tile pressing technology. The investment process, involving the design of the factory and obtaining the required permits, will begin later this year. Construction of the factory and installation of the plant and machinery are scheduled to take place from 2018 until 2020.

Ceramika Paradyż has 28 years of history. An interesting fact is that the company’s ownership structure changed on 18 March 2016. The new owners: Anna Tępińska-Marcinek, Adam Tępiński and Stanisław Tępiński, co-founder of Ceramika Paradyż, gained full control of Ceramika Paradyż sp. z o.o. and Paradyż sp. z o.o.

‘Our family has now become the sole shareholder in Ceramika Paradyż, we thus begin a new chapter in the company’s history’ - said Adam Tępiński, co-owner and CEO of Ceramika Paradyż.

A FAMILY MATTER

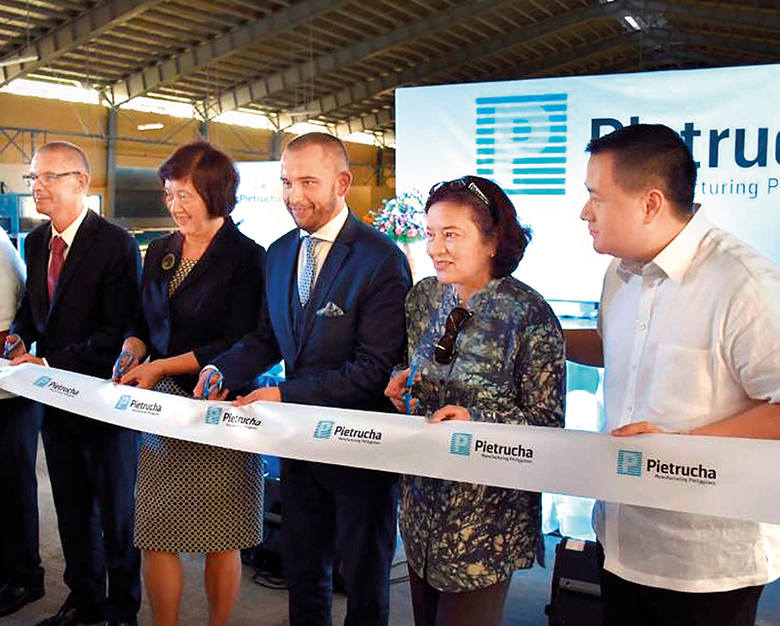

There are more and more family businesses operating in Lodz Special Economic Zone. One such example is Grupa Pietrucha, a company manufacturing specialised geosynthetics, widely used in the construction industry, which it supplies to companies in the land and water engineering industry. The company recently gained a fair amount of publicity when it opened its own factory in the Philippines. This would not have been possible, however, without the company’s earlier development in Ksawerów.

‘We’ve been operating in Lodz Special Economic Zone almost from its inception, as the factory operated by Grupa Pietrucha in Ksawerów was constructed in 2000’, recalled Jerzy Pietrucha, CEO of the company. ‘The factory manufactures sheet piles used in the geoengineering industry. We have clients wherever projects designed to prevent the effects of climatic change are undertaken, including South-East Asia, East Africa and Nigeria. The Ksawerów plant is the parent factory of the plant we erected in the Philippines, where we moved part of our Technology Park and technology. However, this transfer was not to the detriment of Ksawerów and the Zone. We were able to allocate the resources made available thanks to this transfer to research and development activities in order to develop new technologies that will expand our portfolio of products. Our facilities in the Zone will manufacture innovative, next-generation products, while our wares sold in the South-East Asia market will be manufactured locally’, added Pietrucha.

Pietrucha highlighted the excellent relations between his company and the Zone and its employees. ‘We are grateful to the Zone for its support and promotion of Grupa Pietrucha as an investor who was able to find success abroad. It’s a great honour and our motivitation for continued development’, said Jerzy Pietrucha.